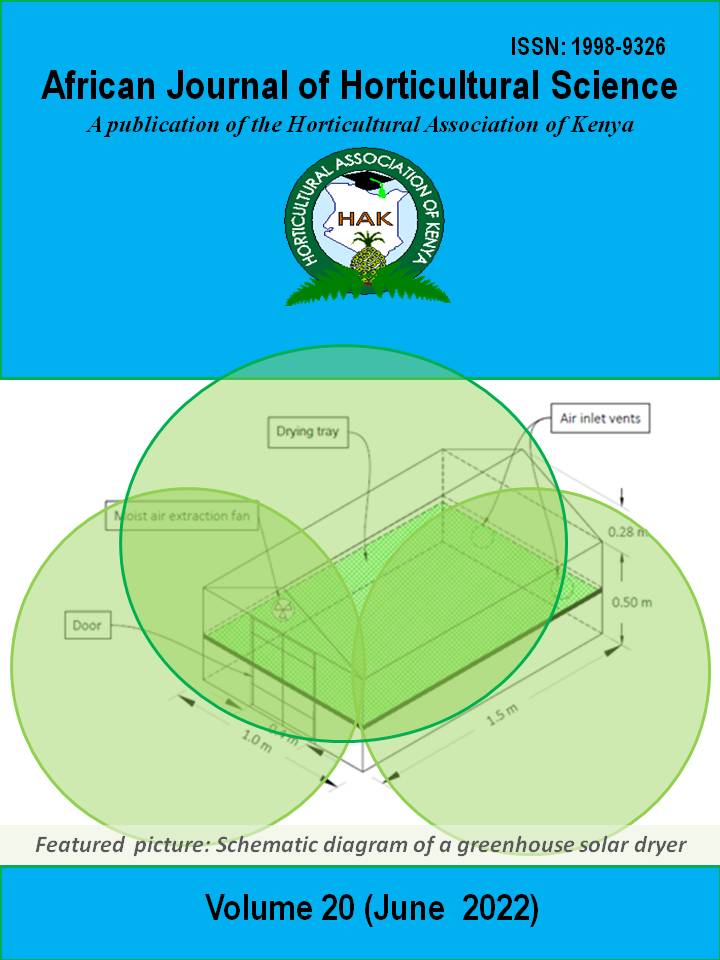

EFFECT OF UV-BLOCKING FILM ON THE THERMAL PERFORMANCE OF GREENHOUSE SOLAR DRYER AND DRYING KINETICS OF TOMATO SLICES

Keywords:

Greenhouse solar dryer, UV-blocking, UV-transmitting, tomatoes, postharvest lossesAbstract

Post-harvest losses particularly in horticultural crops continue to contribute to the already widening gap between food demand and supply. Drying is one of the novel techniques that has been employed to mitigate these losses. Polyethylene films cladded solar greenhouse drying has gained popularity particularly among smallholder farmers in tropical countries. However, there exists no information on their comparative effects on the thermal performance of greenhouse solar dryers and quality of the dried products. The objective of this study, therefore, was to determine the effect of UV-blocking (UVB and UVA) and UV-transmitting polyethylene films on the thermal performance of greenhouse solar dryer and drying kinetics of Kilele F1 tomato slices. Two greenhouse solar driers, one cladded with UV-blocking film and the other with UV-transmitting film, were developed and used to dry Kilele F1 tomato slices. Solar radiation, UV-transmission intensity, temperature, relative humidity, wind velocity, moisture content, and colour were measured periodically in each dryer and the results analysed statistically using STATA SE Version 16.0. Lower average room and ground greenhouse temperature, that is 40.32±6.25 and 45.12±5.86 ºC, respectively were attained in UV-blocking greenhouse solar dryer compared to the respective temperatures, 42.48±6.48 and 46.10±6.33 ºC attained in UV-transmitting greenhouse solar dryer. The 5 mm thick tomato slices were dried from an initial moisture content of 2785.53 % (db) in both dryers to a final moisture content of 34.63 and 34.18 % (db) in UV-blocking and UV-transmitting dryer, respectively, in 12 hours. In addition, an average drying rate of 57.88 (g/g)/hr and 65.02 (g/g)/hr were obtained in UV-blocking and UV-transmitting dryers, respectively. Lower effective moisture diffusivity of 2.03 ×10-10 m²/s was attained in UV-transmitting dryer compared to 2.11 ×10-10 m2/s attained in UV-blocking dryer. While UV-blocking dryer registered better performance in colour retention, UV-transmitting dryer registered higher shrinkage ratio and rehydration ratio. Further, non-linear regression analysis established that Page model provided the best description of the drying kinetics of tomato slices in both dryers with R2 of 0.9962 and 0.9975, χ2 of 0.0004 and 0.0002, RMSE of 0.0190 and 0.0161, for UV-blocking and UV-transmitting dryer, respectively. Therefore, the results indicate that both films can be used in greenhouse solar dryers to dry tomato slices economically without leading to significant physical and nutritive quality deterioration.

Downloads

Published

Issue

Section

License

Copyright (c) 2022 African Journal of Horticultural Science

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.